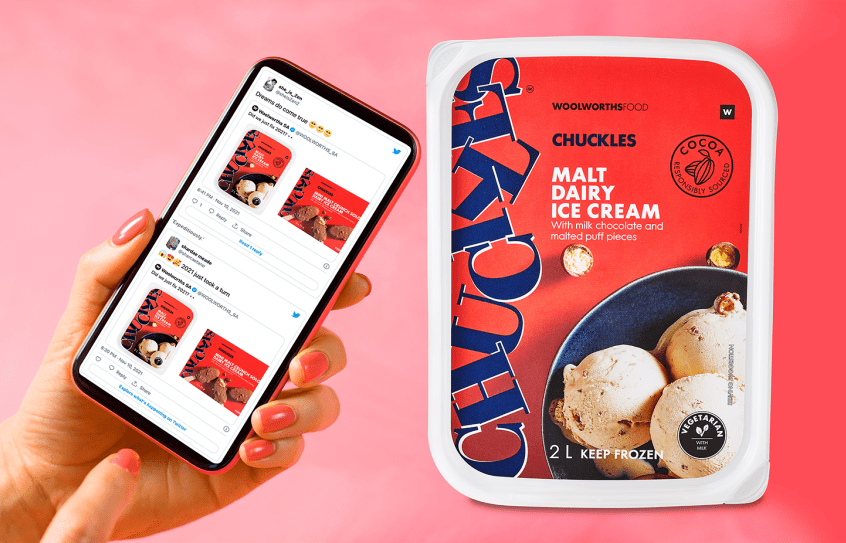

Ice cream

The freezer isle is packed with tempting flavors, colors, varieties and downright delicious brands of ice cream. As an ice cream producer, how do you stand out from this – often strong & seasonal – competition? Numerous IML look and feel options give you a head start in persuading consumers!

Upgrades for your Ice Cream IML labels